MESH Wireless Ad Hoc Network: The Enabling Force for Innovation in the Field of Industrial Automation

Driven by the industrial 4.0 and intelligent manufacturing trends, the industrial automation field has an increasingly urgent demand for efficient, stable and flexible communication networks. The MESH wireless ad hoc network, with its unique technical characteristics, provides strong support for the upgrading and development of industrial automation, and has become an important force driving industry transformation.

I. Communication Challenges in the Field of Industrial Automation and the Advantages of MESH Self-Organizing Networks

Traditional industrial automation networks mostly adopt wired communication methods. However, in complex industrial environments, this approach faces numerous challenges. Factories have numerous devices and complex layouts. Wires for wired networks not only have high costs but also require extensive construction efforts, long construction periods, and are cumbersome to re-plan the wiring when adjusting device positions or adding new equipment later. Moreover, once the wiring of a wired network is damaged, troubleshooting and repair processes are time-consuming and labor-intensive, seriously affecting production progress.

The emergence of MESH wireless ad hoc networks effectively addresses these issues. Its intelligent decentralized architecture enables each node to have routing and forwarding capabilities, eliminating the risk of single-point failures. Even if some nodes fail, the network can automatically adjust the routing to maintain stable communication. The dynamic topology adaptive feature can easily handle network changes caused by the movement, addition, or reduction of devices in industrial scenarios. At the same time, MESH wireless ad hoc networks support long-distance transmission, have bandwidth allocation and dynamic adjustment capabilities, and also possess private network communication and security encryption functions, which can meet the reliability, security, and real-time requirements of industrial automation for data transmission.

II. MESH Wireless Ad Hoc Network in Multiple Application Scenarios of Industrial Automation

(1) Interconnection and Collaboration of Intelligent Factory Equipment

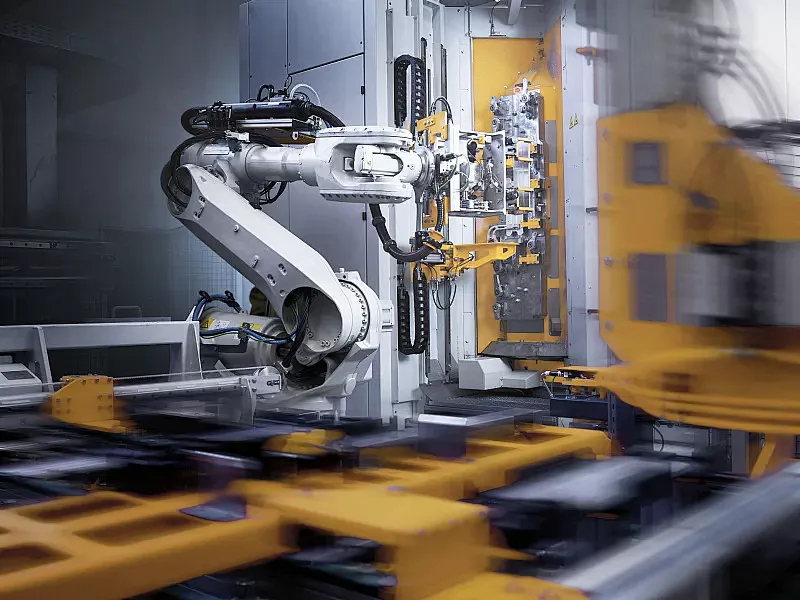

In intelligent factories, a large number of devices such as sensors, actuators, CNC machines, and robots need to achieve interconnection and collaborative work. The MESH wireless ad hoc network can quickly establish a communication network among these devices, making them an integrated whole. For example, sensors on the production line collect real-time data on equipment operation parameters, such as temperature, pressure, and speed, and transmit the data through the MESH network to the central control system. The central control system, based on preset programs and data analysis results, issues instructions to actuators, CNC machines, and other devices to achieve precise control of the production process. At the same time, robots can also collaborate with each other through the MESH network, such as the efficient cooperation between material handling robots and assembly robots, which significantly improves production efficiency and product quality.

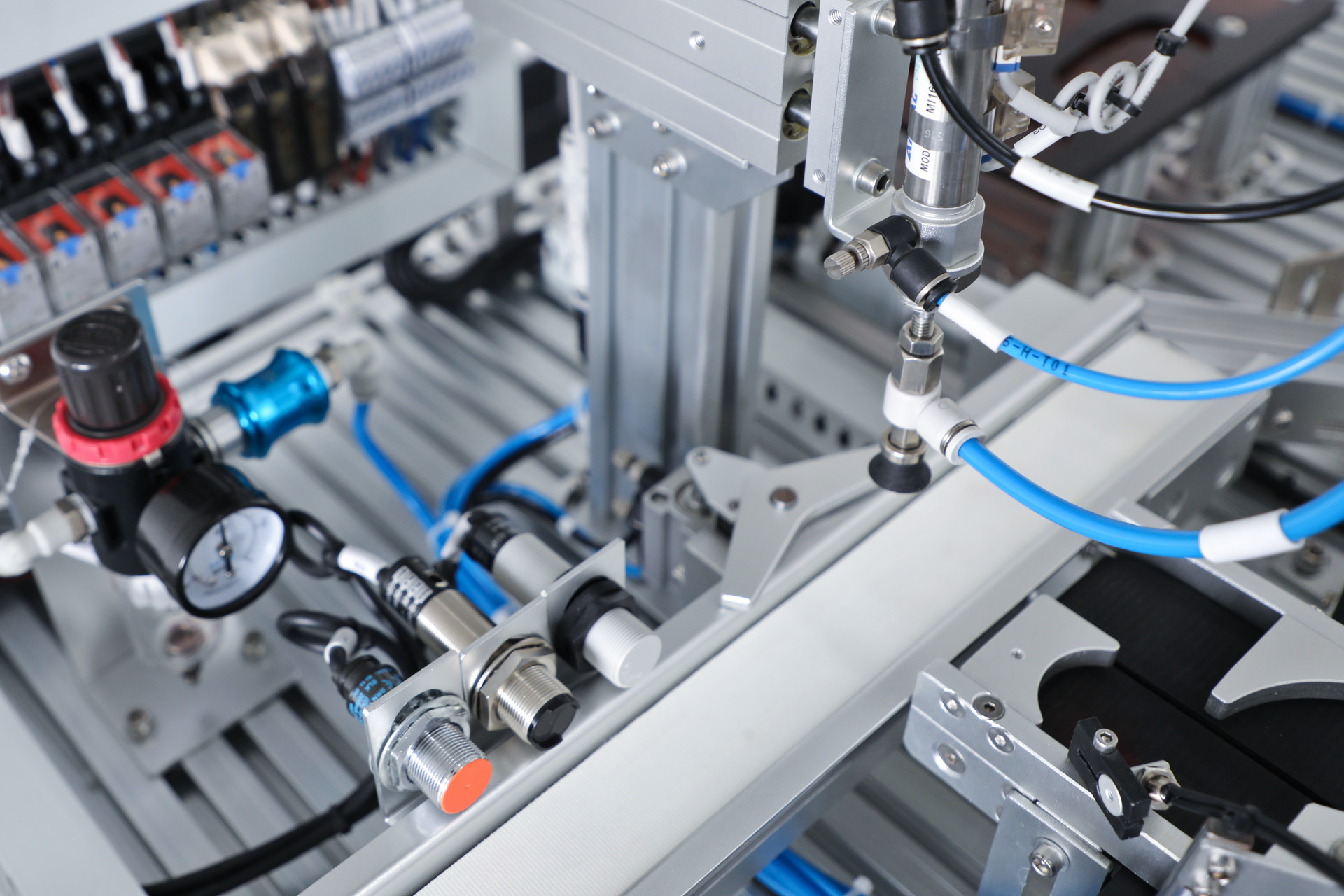

(2) Remote Monitoring and Maintenance of Industrial Equipment

With the help of MESH wireless ad hoc network, enterprises can achieve remote monitoring and operation management of industrial equipment. In large industrial production sites, there are numerous key equipment distributed throughout. By deploying MESH nodes on these devices, maintenance personnel can obtain real-time information such as the operating status and fault warnings of the equipment without having to be on-site. For example, in the power industry, the operating data of equipment such as transformers and circuit breakers in substations can be transmitted via the MESH network to the monitoring center. Maintenance personnel can conduct remote diagnosis of the equipment using data analysis software, promptly detect potential faults, and formulate maintenance plans. For some simple faults, remote control of the equipment can also be used for repair, reducing equipment downtime and lowering maintenance costs.

(3) Rapid Deployment and Adjustment of Flexible Production Lines

With the increasing diversification of market demands, enterprises need to have the ability to quickly adjust their production modes. Flexible production lines have thus emerged. The MESH wireless ad hoc network provides convenience for the rapid deployment and flexible adjustment of flexible production lines. When enterprises need to change the type of products produced or adjust the layout of the production line, they only need to move the equipment to the designated position. The MESH nodes on the equipment will automatically search for and connect with surrounding nodes, and re-establish the communication network. This ability to quickly form a network enables the production line to complete adjustments in a short time and be put into production, significantly improving the enterprise's response speed to market changes.

III. Typical Cases of MESH Wireless Ad Hoc Network in the Field of Industrial Automation

A large automobile manufacturing company has introduced MESH wireless ad hoc network technology in its newly-built intelligent factory. In the four major production workshops - stamping, welding, painting, and assembly - a large number of automated equipment have been deployed, including stamping machines, welding robots, painting robots, AGVs (automated guided vehicles), etc. Through MESH wireless ad hoc network, high-speed data transmission and precise collaboration between the equipment have been achieved.

In the welding workshop, the welding robots receive welding parameter instructions from the central control system through the MESH network and feed back real-time data during the welding process to ensure the consistency and stability of the welding quality. The AGV vehicles freely move around the workshop and communicate with other devices and systems through the MESH network, achieving precise material distribution and efficient circulation. After introducing the MESH wireless self-organizing network technology, the production efficiency of this factory has increased by 20%, the equipment failure rate has decreased by 15%, and significant economic benefits have been achieved.

IV. Future Trends and Challenges

Although MESH wireless ad hoc networks have demonstrated great potential in the field of industrial automation, they still face some challenges. In terms of cybersecurity, industrial production data involves the core secrets of enterprises. If leaked, it will cause serious losses. Therefore, it is necessary to continuously strengthen encryption technologies and security authentication mechanisms. At the same time, as the level of industrial automation continues to increase, the requirements for network bandwidth and transmission rate are also growing. MESH wireless ad hoc networks need to further optimize their technologies to meet higher performance demands.

In the future, MESH wireless ad hoc networks are expected to further integrate with technologies such as 5G, the Internet of Things, and artificial intelligence, bringing more innovative applications to industrial automation. For instance, when combined with artificial intelligence, it can achieve intelligent autonomous optimization and fault prediction of the network; when integrated with 5G, it can enhance the speed and stability of data transmission, and drive industrial automation to a higher level.

The above content focuses on the application of MESH wireless ad hoc networks in the field of industrial automation. If you would like to know the details of the application in specific industrial scenarios, or if you want to have an in-depth discussion on the technical implementation part, feel free to let me know at any time.

-

2025-10-28

-

What Is a Mesh Network Radio and How Does It Work?

2025-10-14 -

How to Set Up a Wireless Self-Networking Station in Remote Areas

2025-09-16 -

What Is an Outdoor Wireless Bridge?

2025-08-29 -

MESH Self-Organizing Network Communication Systems: Principles and Future Prospects

2025-08-18 -

Understanding the 4 Major Types of Microwave Transmission

2025-07-30