Implementation Plan for Wireless Transmission of Online Monitoring System for Power System

I. Current Situation and Demand Analysis of the Electric Power Industry

With the rapid development of China's national economy, the demand for energy in all industries is also increasing day by day. For the power industry, which provides the main energy for the society, its social responsibility is becoming increasingly significant. The power industry provides continuous power energy for the development of the social economy. The transmission lines, high-voltage towers, substations and other facilities distributed all over the country need a large amount of manpower and material resources to ensure the reliable operation of these basic equipment during daily operation. Since most of these facilities are in places where it is inconvenient for people to reach, the power maintenance personnel have great inconvenience in daily maintenance. If problems occur and cannot be identified within the shortest time, an effective system for online monitoring and management is urgently needed.

In order to ensure the safe, stable and reliable operation of the power transmission lines, the power company has proposed installing video monitoring systems on the transmission towers, so as to quickly detect potential hazards and problems and solve them. With the comprehensive renovation of the power network, a large number of transmission high-voltage towers, substations and power stations are required to be unmanned, in order to improve production efficiency. Currently, the power bureau has set up operation management duty rooms and dispatch departments, and establishing a technologically advanced and powerful monitoring system has been put on the agenda of the power department's development. The power monitoring system is established in the power dispatch communication center to set up a monitoring center, so as to monitor and supervise the relevant data, environmental parameters and images of each substation and power station, in order to be able to understand and grasp the situation of each substation and power station in real time and directly, and respond promptly to the situations that occur, to meet the needs of modern society's development.

II. Scheme Thinking and Design

In response to the specific needs of the power industry, our company has proposed a complete wireless transmission solution. During the process of designing the solution, the following points were fully taken into consideration:

1. The feasibility and stability of the wireless transmission solution. In the design of the integrated solution, the fundamental prerequisite is the feasibility and stability of this solution. Without this as the foundation, everything else is useless. For the power industry, which faces the challenge of inconvenient cable installation in the field, our company has introduced digital wireless bridges as the transmission medium. According to the different applications and requirements of each point, different models of equipment are selected, combined with different antennas, so as to achieve the feasibility of communication for the entire communication link. Regarding the stability of the architecture, feasibility is the foundation, while stability is the key to the entire transmission process. The wireless bridges produced by our company have been well verified in previous engineering projects in terms of production processes and transmission performance.

2. Expandability of the overall wireless solution design. The success of a project implementation not only depends on whether the equipment can operate normally after it is set up at that time, but also on whether the subsequent needs of the customers can be taken into account and additional expandability is provided. This requires that during the initial solution design, the special circumstances that may arise during or after the implementation of the user's project should be considered. If equipment is added to the user's original solution without incurring excessive costs. Therefore, in the design of this solution, we have provided the user with a large amount of redundancy. This is to facilitate the user's addition of other monitoring points in the future.

3. Usability of equipment maintenance in the later stage. After the entire system is set up, problems are inevitable during the users' operation. Considering that the personnel at the user's site do not possess high professional technical operation capabilities, during the initial system design, each part should be designed as simple, easy to use and stable as much as possible. Each component should be made as modular as possible to reduce the difficulty of operation and maintenance for the operators.

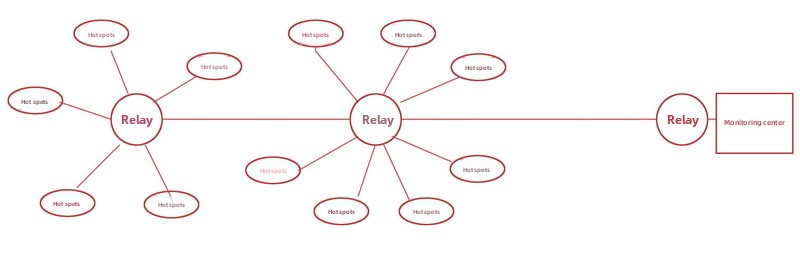

Based on the above considerations, the specific design of the plan is as follows. It is mainly divided into three parts:

Front-end video, data collection, voice output and wireless transmission components;

The intermediate hotspot wireless coverage and point-to-point wireless transmission section;

The display, control and database access components of the backend monitoring center.

As shown in the following picture:

The distance from the hotspot to the relay point is approximately within 10 kilometers, while the distances between relays and between relays and the backend monitoring center are roughly within 30 kilometers. Below, we will specifically explain how these three parts are implemented.

2.1, Front-end video, data collection, voice output and wireless transmission section

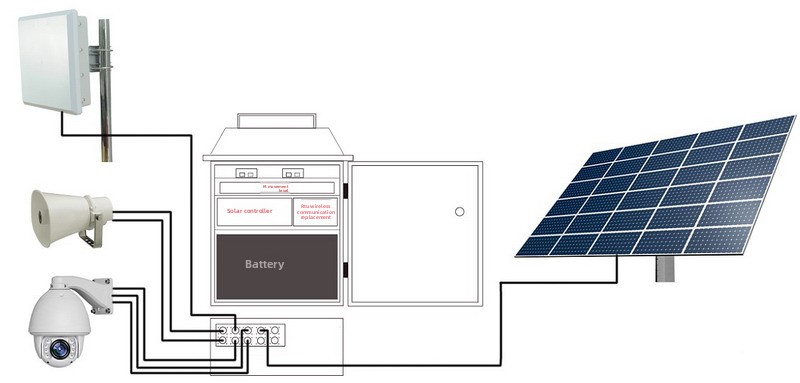

At the power transmission site, the front-end of the user generally includes common functions such as video capture, data control, voice output and wireless transmission. The video capture part of the user uses high-definition digital network dome cameras (the model is yet to be determined, requiring the ability to connect to the data platform), which can comprehensively monitor the on-site environment at the front end. The personnel in the back-end monitoring room can also operate and control the rotation and zoom of the front-end images using keyboards and mice.

The solution for the voice output part is as follows: Connect the voice output interface of the digital network dome camera to the input interface of the amplifier, and then connect the amplifier to the high-power speakers. Since the monitoring points at the front end and the monitoring center at the back end are on the same local area network, the wireless announcement function from the back-end monitoring center to the front-end can be realized.

The wireless transmission part adopts our company's TQ-5040G digital wireless bridge. This device is equipped with a 18dbi flat antenna, and the transmission distance can reach up to 10 kilometers, fully meeting the wireless signal connection from the front end to the hotspot base station. The transmission performance is stable and reliable. (The specific parameters of the equipment can be found in the attachment.) The switch aggregates the network cameras and other digital devices at the front end and connects them to the data interface of the POE power supply box of the TQ-5040G, and transmits these signals wirelessly to the base station covered by the hotspot.

The device connection topology diagram for this section is as follows:

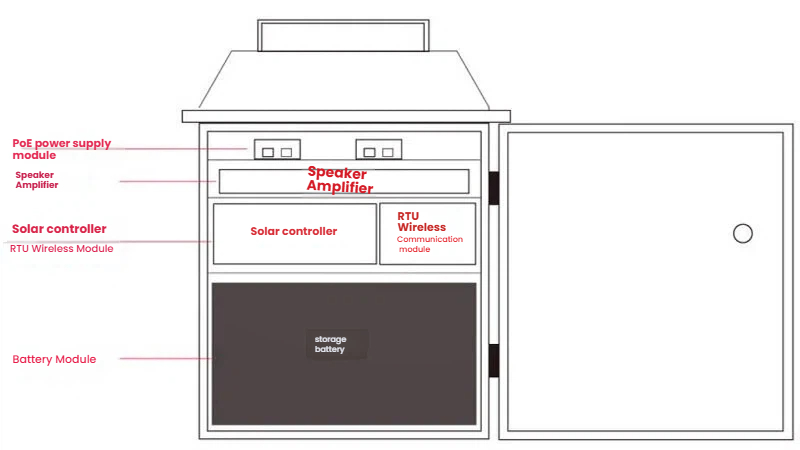

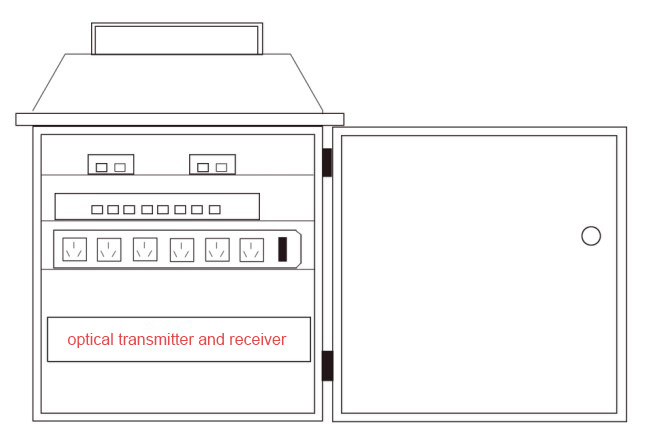

The power supply for the front-end part adopts the solar power supply solution.

To use a distribution box, a POE power supply box for wireless devices, RTU wireless communication module, solar controller and battery, etc. should be placed inside the distribution box. A 100AH battery should also be placed inside the distribution box. At the same time, the solar controller and inverter should also be placed inside the distribution box. The other interface should be connected to a 150W solar panel.

As shown in the following picture:

The overall connection diagram of the key equipment is as follows:

2.2, Wireless Coverage at Relay Points and Point-to-Point Wireless Transmission Section

For the base station relay point part, we have adopted our company's high-bandwidth multi-module wireless transmission product, model TQ-5000MS series. The specific model for the product that provides wireless coverage for the base station is TQ-5000MS-02H. The reason for using this equipment as the wireless coverage product is that this product is designed with a gigabit network interface and has a high data processing capability. The equipment itself supports a multi-module design, allowing for the installation of two modules. During the actual hotspot coverage process, if only a omnidirectional antenna is used, the gain is too small and cannot achieve a relatively long transmission distance. Therefore, in the scheme design and product selection, this equipment was used. In one device, two 60-degree antennas can be installed, and in this base station, two devices can install four 60-degree antennas. The combined coverage angle can reach more than 240 degrees, which can basically meet the connection requirements of the surrounding front-end wireless devices. As shown in the figure below:

Two units of this type of wireless equipment are installed on the tower. Each unit can accommodate two antennas, and the two units can collectively install four antennas, in order to achieve wireless coverage for the surrounding area.

For point-to-point communication, the wireless equipment we recommend is our TQ-5000MS25. This device is equipped with a 25dBi directional gain antenna. Due to the high transmission power of the device itself, the transmission distance can reach up to 30 kilometers. As a wireless transmission device between base stations, this device has many advantages. It has a built-in gigabit network interface, stable working performance, and the theoretical transmission bandwidth can reach 480 Mbps. The actual measured transmission bandwidth can reach 160 Mbps. This device has the characteristic of multi-level relay without loss, which can ensure a high bandwidth data even after multiple relays. The data loss during the transmission process is very small (the detailed parameters of the above two devices can be referred to in the product descriptions attached in the file). At the installation location of the base station equipment, the power supply method is the same as the front-end power supply method. Under normal circumstances, it is powered by AC 220V. If in some special situations, there is no city power supply, the above solar power supply system can also be adopted.

Point-to-point distance-free transmission is shown in the following diagram:

The distance between hotspots is quite far, so the TQ-5000MS25 is used for directional transmission to ensure that the monitoring data and images from the front end can be stably transmitted to the monitoring center.

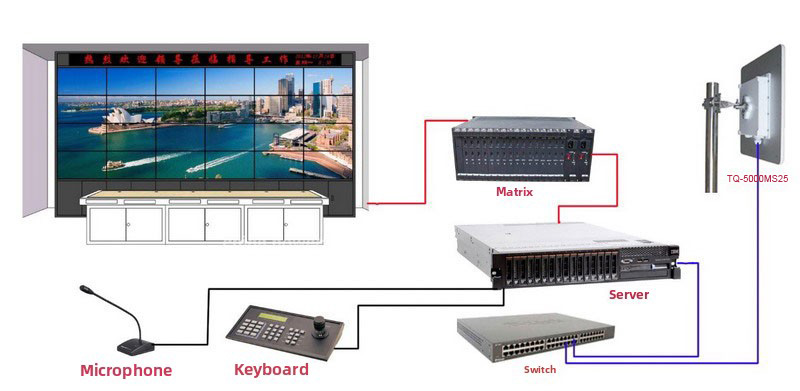

2.3, The display, control and database access components of the backend monitoring center

After the back-end monitoring center receives the monitoring images from the front-end through wireless devices, since the monitoring center is usually located in the urban area and its location is relatively low, it is necessary to find a high-rise building near the monitoring center and install wireless receiving equipment on the top floor of the building to receive the wireless signals transmitted from the relay point. A distribution box also needs to be configured on the roof, as shown in the following figure:

The signals received by the wireless bridge enter the optical terminal equipment from the switch, and are transmitted via optical fibers to the computer room. They are then connected to the server of the monitoring center. The server is equipped with an online monitoring platform for the power industry. Through this data monitoring platform, the images from the front end can be viewed and managed. They can also be projected onto large screens through the wall-mounted server or the matrix.

A server is set up in the monitoring center, with the power system online monitoring platform installed on it. Then, through wireless receiving devices, the monitoring images and data from the front end are received by the monitoring platform. Through a microphone, shouting can be conducted to the front end. At the same time, the front-end cameras can be controlled through the control keyboard. On the background server, RTU control software is installed, which can remotely send instructions to the front end equipment, enabling remote power-on and power-off operations of the front-end devices.