Industrial MESH Networking Equipment Selection Guide

In modern industrial environments, the demand for stable, scalable, and intelligent communication networks is growing rapidly. Whether it’s for factory automation, smart grid applications, mining, oil & gas, or remote environmental monitoring, wireless MESH networking has become a go-to solution for reliable and flexible data transmission. But selecting the right industrial MESH networking equipment requires careful consideration of environmental conditions, network performance needs, and future scalability.

What Is Industrial MESH Networking?

MESH networking is a decentralized communication system where each device (node) can connect to multiple other devices, forming a web-like structure. In industrial settings, this means that even if one node fails or a connection is lost, the network can automatically reroute data through other nodes. This self-healing capability ensures higher reliability and fault tolerance compared to traditional point-to-point or star networks.

Key Advantages of MESH Networking in Industry

Reliability and Redundancy: Data can travel across multiple paths, ensuring continuous connectivity even in case of node failure.

Scalability: Nodes can be added easily without major infrastructure changes.

Flexibility: Suitable for dynamic environments where layouts and equipment may frequently change.

Self-healing and Adaptive: The network can automatically adjust to changes or interference, minimizing manual configuration.

Cost-effective Deployment: Fewer base stations and long-distance cables are needed.

Factors to Consider When Selecting MESH Networking Equipment

1. Communication Frequency and Bandwidth

2.4GHz: Offers longer range and better penetration through obstacles but can be crowded in environments with many Wi-Fi devices.

5.8GHz: Provides higher data rates and less interference, but with a shorter range.

Sub-GHz (e.g., 433MHz or 868MHz): Better for long-distance transmission and low power consumption, ideal for sensor networks in wide outdoor areas.

2. Data Throughput Requirements

For real-time applications like video surveillance or automated control systems, higher throughput and lower latency are crucial. Choose MESH equipment that supports high-speed data rates, stable performance under network load, and advanced QoS mechanisms.

3. Range and Coverage

Industrial environments may span large areas with significant physical barriers. Select equipment with high transmission power, directional or omnidirectional antennas, and advanced routing protocols that support long-distance multi-hop communication.

4. Network Topology and Node Capacity

Some MESH systems can support hundreds of nodes in a single network. Evaluate how many devices you plan to connect, and whether the equipment can handle dense or complex topologies.

5. Power Supply and Energy Efficiency

In remote or mobile applications, nodes may rely on solar or battery power. Energy-efficient MESH nodes are essential in such cases. Look for low-power modes, wake-up-on-demand features, and minimal idle consumption.

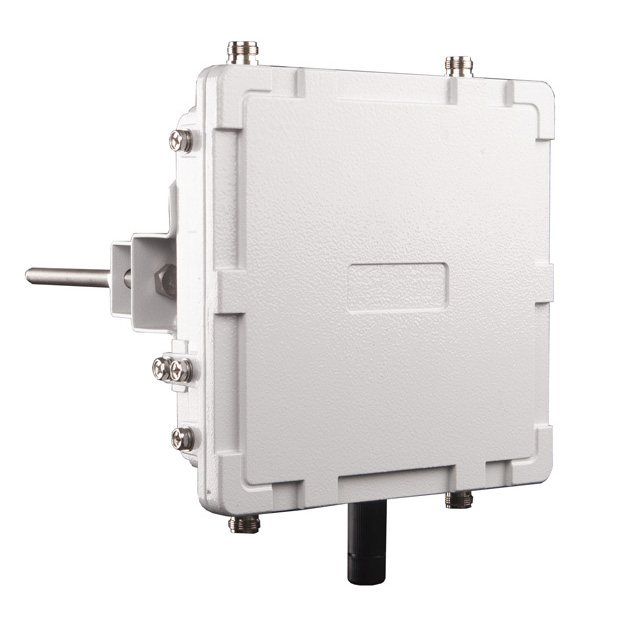

6. Industrial Grade and Environmental Resistance

Industrial-grade equipment must withstand extreme temperatures, humidity, dust, and vibration. Verify IP ratings (e.g., IP67), temperature range (e.g., -40°C to +85°C), and ruggedized enclosures for outdoor or hazardous environments.

7. Security Features

As networks become more connected, cybersecurity is critical. Choose equipment with built-in encryption (AES-128 or AES-256), secure key exchange protocols, and firewall or access control features.

8. Ease of Configuration and Management

Look for user-friendly network management tools that support remote monitoring, firmware updates, and diagnostics. Automatic network configuration, drag-and-drop topology visualization, and real-time performance analytics are beneficial.

9. Integration and Compatibility

Ensure compatibility with your existing systems—whether it’s Modbus, TCP/IP, RTU, OPC UA, or SCADA. Some advanced MESH devices also offer integration with cloud platforms or edge computing capabilities.

Typical Application Scenarios

Smart Grids: Remote metering, substation communication, distributed automation

Industrial Automation: AGV (Automated Guided Vehicles), sensor networks, robotic arms

Oil & Gas: Pipeline monitoring, gas leak detection, offshore platform communication

Mining: Underground tracking, ventilation control, environmental monitoring

Municipal Infrastructure: Smart street lighting, surveillance, traffic systems

Conclusion: Choosing the Right Partner Matters

Industrial MESH networking is a powerful solution for modern industrial connectivity, but the success of deployment hinges on choosing the right equipment and partner. With a multitude of environmental and operational variables, it’s vital to work with a provider that understands your application needs and delivers robust, field-proven solutions.

About TuQian Wireless

TuQian Wireless is a trusted provider of industrial-grade wireless communication solutions specializing in MESH networking, wireless video transmission, and power management systems. With a product portfolio that includes single-soldier standard-definition transmitters, vehicle-mounted HD MESH devices, 2.4G glass fiber antennas, and solar energy power packs, TuQian Wireless is committed to delivering reliable, secure, and scalable wireless solutions tailored for harsh industrial conditions.

Backed by years of technical innovation and real-world deployment experience, TuQian Wireless empowers clients across sectors like public security, energy, mining, and smart cities to build high-performance communication networks that withstand the test of time and environment.

-

2025-10-28

2025-10-28 -

Applications of IP Mesh Radios in Military and UAV Communication

2025-10-28 -

What Is Long Distance Communication and How Does It Work?

2025-10-20 -

What Are the Four Types of Wireless Data Transmission?

2025-09-11 -

Which Wireless Technology Is Used for Long Distance Communication?

2025-09-02 -

How High-Bandwidth MESH Communication Devices Ensure Stable Wireless Video Transmission

2025-08-28 -

How Does Microwave Power Transmission Work?

2025-08-18 -

What Is Microwave Transmission?

2025-07-30